Arri Technical Advisory

Arri has recently released a video regarding the dangers of hot-plugging accessories that connect to cameras via SDI. Arri previously released a technical advisory on the subject in March 2018, but has recently re-released it with an accompanying video, which can be seen below:

After this video was released, we at Rencher Industries have received several inquiries about the issue, and it appears that many operators and assistants don't quite understand what is happening when hot-plugging a device.

Hot-Plug

If you are not familiar with the term hot-plug, it's pretty simple. Hot-plugging in the computer world is the addition of a component to a running computer system without significant interruption to the operation of the system. In the electrical world, hot-plugging is somewhat related to breaking capacity, meaning a connection that has breaking capacity has the ability to be connected or disconnected while live and under load.

To clarify further, when your camera is on and supplying power to its accessory outputs, and a device that is drawing or will immediately draw current is subsequently connected or disconnected, that is hot-plugging. If the connections have breaking capacity, then they are designed in a way not to arc, but to instead connect your terminals in the proper order.

What Arri explains in their video is also pretty simple: in order for your accessory power cables to have breaking capacity, the shield of the cable needs to be connected to both connector housings. This is to ensure that common voltage (negative voltage, or ground) is connected first, before the pins inside the connectors mate with the power receptacle. The shield is key here because most sensitive electronic devices have their cases attached to the negative battery terminal at some point in the system. If you are powering equipment from AC power, it is possible to introduce ground loops if there are multiple paths to ground. I could easily get lost on a tangent about ground loops and the interference it can cause, but that is a topic for another day.

The Damage

Another key piece of information that the advisory warns, is where the damage really occurs: in the SDI driver chips. BNC connectors are coaxial connectors, which means that the common voltage (commonly referred to as “ground”) is carried through its shield. This shield is also connected to the case of the camera, thus connecting the signal common with the case common voltage. Since the case ground is connected to the negative battery terminal, any of the BNC connections can become a stray path to the negative battery terminal to complete a circuit. The center pin of the SDI line can also lead to ground; more on that later.

I know this sounds complicated, so I’ll try to unpack things a bit. Electricity always seeks to flow from a higher voltage to a lower voltage through the path of least resistance. Arri has stated that the accessory power connectors do not have breaking capacity, if the shields aren’t connected. This is because without that shield connection, there is a chance that the positive terminal of the Lemo or Fischer connector can make contact before the negative terminal does. This happens because the negative and positive terminals are the same size and length. If the positive terminal connects first, even for a miniscule amount of time, that circuit can be completed by the SDI lines.

Since the SDI lines are at logic-level, meaning they are designed for very low voltage and current, a buildup of power can destroy components on the SDI board in the same way a fuse would blow when there is a short-circuit. Logic-level is usually represented by the voltage difference between the signal and ground. In its simplest terms, the signal on the center pin of an SDI line will fluctuate between high (positive voltage) and low (0 voltage, or ground), and that has some important implications, which I will go into below.

After initially publishing this article, I was contacted by the product manager for the Alexa Mini line of cameras, Michael Jonas. He made a few points about what is happening to the SDI boards that I felt were of value to share. First, the current, not the voltage, is what causes damage to the SDI boards. As mentioned above, when power is connected to the camera without a ground connection, the circuit is completed through the SDI lines. The SDI shield actually pulls about 2/3rds of the current, but since the SDI center pin is at logic-level, about 1/3rd of the current is pulled through that center conductor; that is truly what causes the damage.

This problem is not limited to Arri cameras. It is a common problem on pretty much all cameras. Michael also explained to me that in 12G SDI, which the Alexa Mini LF supports, there is no way to build-in protection against this damage. It was conveyed to me that Arri discovered this, and brought it to the attention of Blackmagic Design, which actually develops 12G SDI technology. Arri has been improving their design to mitigate damage in the SDI boards of all causal types, and as of this writing, they are on Revision H (the 8th revision) of their SDI boards.

There is another issue that accounts for SDI board damage caused by large currents and that is something called inrush current. An inrush current is a large pull of power that happens when a piece of electronic equipment is turned on. It’s caused by components like capacitors charging up, pretty much instantaneously. We can use TVLogic monitors as an example. In their testing, Arri found that TVLogic monitors can pull as much as 9 amps when the power switch is flipped on. This current lasts only for a split-second, but that is all it takes to cause damage in sensitive electronic circuits if that current travels through the SDI lines.

Another very important aspect of this issue is the proper maintenance of coaxial cables used for SDI signals. Arri has stated that their SDI boards can deal with a certain bit of damping caused by a weak signal-ground connection through the SDI Lines, but a broken SDI cable shield can cause the current to sink through the coaxial center pin and damage the board. Basically, the SDI signal can still exist without the SDI ground because the power ground still exists through the power cables. In summary, the camera can be damaged if your SDI cable has no continuity through the cable shield, so it is important to test your cables regularly. I will explain how to test for continuity below.

The Solution

So you may ask, what can I do to avoid blowing the SDI boards up? That’s a good question, and it is actually easy to avoid when leveraging best-practices which are shared below:

- Do not hot-plug your accessories

- This means that you should avoid adding an accessory to the system either while power is being supplied from the accessory power connector (turn the camera off first or disconnect the power supply), or

- Do not add an accessory that has no physical on/off switch while power is supplied to the accessory power output connector - Many devices are either always-on while power is present, or have a soft-power button (standby button). A physical switch to disconnect power will keep a circuit from forming through the case ground to the BNC cable.

- Always connect coaxial connections last and disconnect them first

- This will keep the power ground connected so that the signal ground through the coaxial connection won’t be the easiest path to ground and complete the circuit.

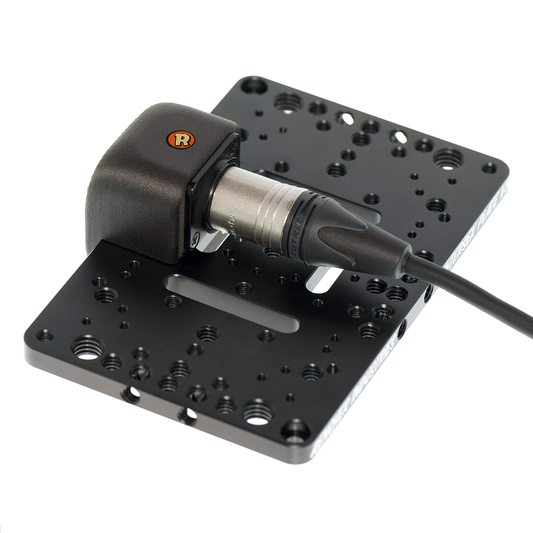

- Use accessory power cables with cable shields or drain wires connected to connector housings on both sides

- This is where a little bit of misconception creeps in. A shielded cable will not eliminate the problem if the shield is not connected to the case ground on both devices. This is why Arri advises to avoid P-Tap (also called D-Tap) connectors (more on this below).

The Deal with P-Tap

Okay, so now for the P-Tap issue. A P-Tap connector features a plastic case that houses two miniature banana pins. The reason that Arri advises against using these connectors is because the plastic housing cannot be tied to the cable shield (plastic is non-conductive). P-Tap cables can be made in a way that connects the shield to the negative battery terminal; this is accomplished by soldering the cable shield directly to the negative terminal in the P-Tap connector. This is standard practice here at Rencher Industries, and I believe that Arri incorporates this as well, but tying the cable shield to the ground does not give the P-Tap breaking capacity itself. P-Tap connectors should never be hot-plugged. Tying the cable shield to the ground will only help if the P-Tap is connected to power before the output connector is plugged into a device, and that is assuming that the ground connection is present through the cable shield to the device’s case ground.

This issue with the P-Tap connector could be resolved if it were redesigned to offset the ground pin so that it mates with the receptacle before the positive pin, and Arri has said that they are looking into that.

The SafeTap Situation

This section has been updated with the introduction of SafeTap Revision 4, which changed from high-side switching to low-side. The SafeTap rev 4 will disconnect the positive line while it checks your power source, eliminating the possibility that the ground line will be connected first. It is recommended to use SafeTap revision 4 or newer over previous revisions or a standard P-Tap/D-Tap in all situations.

It was brought to my attention via a client that there is a blog on Newsshooter that claims that the SafeTap (prior to rev 4) and its protection features is a viable work-around for using P-Taps in a way that will mitigate the problem described in the Arri technical advisory. Finding this claim to be dubious, I actually put a SafeTap up on my bench to test this theory myself and found that the information in the article is not accurate. A SafeTap (prior to rev 4) should not be relied upon to protect against this specific problem. In fact, it can actually worsen the issue. We do not recommend using SafeTap revisions prior to rev 4 for hot-plugging or when coaxial lines are already connected to your camera. In fact, we do not recommend connecting the output side of a SafeTap cable (prior to rev 4), turning on any devices, or plugging in any SDI lines until the SafeTap flashes green and connects the ground line.

For additional context, upon testing, I found that the SafeTap revisions prior to rev 4 disconnect the ground line instead of the positive line (like a transistor). This means that if you have a stray path to ground, (a BNC shield in this case) the positive voltage line will instantly connect, defeating the SafeTap's (prior to rev 4) protection features entirely. Even if the cable shield is connected to the SafeTap’s (prior to rev 4) negative output terminal, the positive line will always directly connect if there is another ground connection available.

Testing Your Cables

So how do you determine if your cables are shielded and that the shields are connected to each connector housing? The good news is that there is an easy way to test this! You will need a multimeter in order to test, and I strongly recommend that every AC or camera tech own one. Prices vary widely, but they can be had for as little as $10. We use Fluke Multimeters here because we trust this brand and require the right tool for the job!

How to test for proper cable shielding:

- Set your multimeter to the “continuity” setting

- If your multimeter doesn’t have this setting, you can also try the “diode” or “ohms” settings

- Refer to your multimeter’s manual for more instructions

- Touch one probe to each connector housing

- This only works with connectors that have metal housings, which is why P-Taps are not recommended

- If testing P-Tap, touch one probe to the metal connector housing, and touch the other probe to the negative battery terminal in the P-Tap connector itself

- Read the output

- You should get a solid chime or visual affirmation that there is strong continuity between the two probes

- Refer to the manual for what reading you should get when using the modes listed above

- That’s it. That is really all you have to do!

This blog post may be updated at a later date for clarifications or corrections. Please reach out if we can help out with this or any other issue! Read the Arri technical advisory here.

[02/21/2020 - This article was updated to include information about the Lentequip SafeTap prior to Revision 4.]

[02/25/2020 - This article was updated to include information provided by Michael Jonas, project manager of the Alexa Mini product line at Arri]

[10/05/2021 - This article was updated to include information about the Lentequip SafeTap Revision 4.]